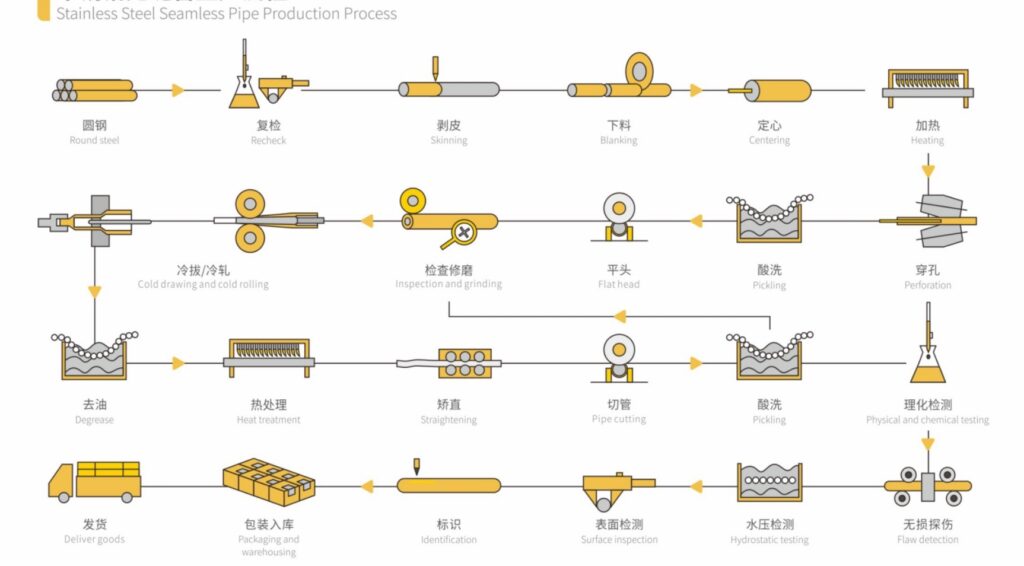

The manufacturing process of seamless pipes is a meticulous and technical procedure, essential to understand for businesses like SteelMerge, which specializes in stainless steel seamless pipes. Here’s a detailed overview of the process:

- Raw Material Selection:

- The process begins with selecting high-quality steel billets or round bars, typically made of stainless steel, carbon steel, or alloy steel.

- Heating:

- The steel billets are then heated to a high temperature in a rotary hearth heating furnace to make them malleable.

- Piercing and Rolling:

- Piercing: The heated billet is pierced through the center using a piercer, which creates a hollow shell or mother tube.

- Rolling: The hollow shell is then passed through a series of rolling mills to reduce its diameter and wall thickness to the desired size.

- Sizing and Stretch Reducing:

- The tube passes through a sizing mill where rollers precisely shape it to the required diameter and wall thickness.

- In some cases, a stretch reducing mill is used for further diameter reduction without changing the thickness.

- Heat Treatment:

- After sizing, the pipes undergo heat treatment to achieve desired mechanical properties. This may include normalizing, quenching, and tempering processes.

- Surface Finish Processing:

- The pipes are then processed for surface finish. This can include pickling to remove scale, cold drawing for precise dimensions and smooth surface, or annealing for improved ductility and hardness.

- Straightening and Cutting:

- Pipes are straightened if necessary and then cut to the required length using saw cutting or plasma cutting methods.

- Inspection and Testing:

- Various tests are conducted to ensure quality, including hydrostatic test, ultrasonic test, eddy current test, and mechanical tests (tensile, yield, elongation).

- Dimensional inspection is also performed to ensure the pipes meet specified tolerances.

- Finishing:

- Pipes are then finished as per customer requirements, which may include beveling the ends, marking, and coating.

- Packaging and Dispatching:

- Finally, the pipes are bundled, packaged, and dispatched. Packaging is done carefully to prevent damage during transportation.

The seamless pipe manufacturing process is complex and requires precision at every step to ensure the highest quality product. For companies like SteelMerge, which cater to a global clientele including Pakistan, Turkey, Russia, India, and Singapore, understanding and controlling this process is crucial to ensure the delivery of top-quality stainless steel seamless pipes that meet the specific needs of manufacturers, distributors, traders, and project constructors. By emphasizing rigorous quality control and customization capabilities, SteelMerge can provide its customers with products that meet their exact requirements in terms of dimensions, material grade, and performance specifications.